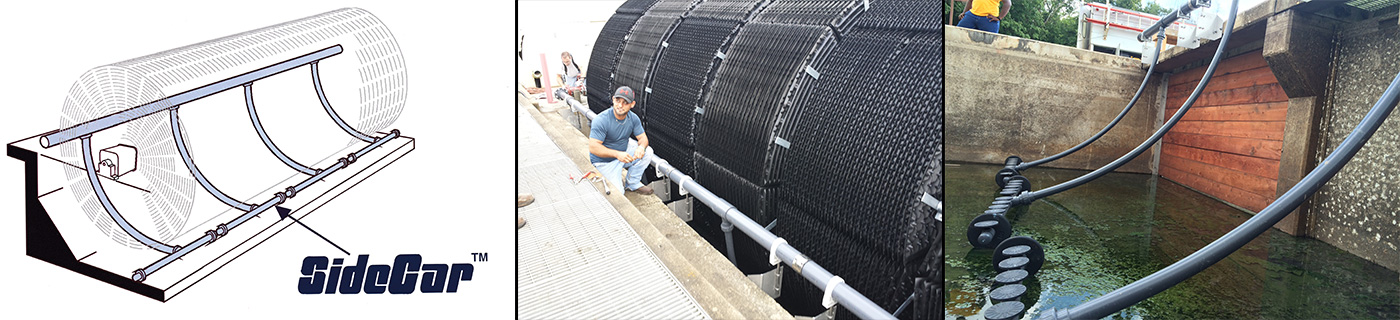

For biological process enhancement and/or to extend mechanical life of equipment through biomass weight control, SideCar is the most efficient and economical choice in RBC aeration.

The SideCar™ system was developed to meet the definitive needs of RBC aeration for new and existing plants. SideCar systems are specially designed for each plant, complete with all installation, drawings and instructions and fittings and supports, assuring convenient installation and optimum process air control and distribution.

Multi-shaft RBC Plant with air supply headers for SideCars™ above enclosures

conveniently supported by drop pipes.

LIKELY CANDIDATES FOR SIDECAR AERATION

Both existing and new RBC systems benefit from SideCar aeration. Plants with one or more of the following conditions are likely candidates for SideCar aeration:

- RBCs that have exhibited or are at risk of shaft, media or media support failures from excessive biomass loads.

- Heavy biomass with white and/or black blotches with difficult-to-settle floc.

- Improperly sized or overloaded RBC systems or stages.

- Plants that receive high soluble BOD loads from industrial contributors or inplant returns.

- Systems at or near design load requiring additional treatment capacity.

- Those plants treating septic wastewater where sulfur compounds produce undesirable growths.

- RBC plants with odor problems.

An impressive body of case histories confirm practically all RBC media configurations respond with improved treatment when aerated.