SideCar aeration systems comprise pipe, fittings, supports and air diffuser components to conveniently outfit RBC’s in concrete or steel tanks. (To [complement] assure convenient installation [SideCar components,] Mooers products provides custom drawings,installalation and systems operations instructions and)

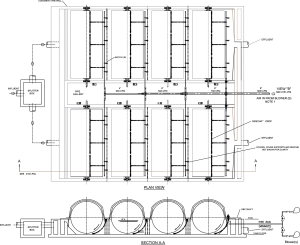

A typical system has multiple SideCar diffuser subassemblies, fabricated of heavy duty schedule 80 PVC pipe and fittings, each consisting of a UNION (or UNION VALVE for multi-stage RBCs), a DROP PIPE (configured to fit between the RBC and tank wall) and an AERATION HEADER. Size and length of the headers are dependent upon the length of RBC tank and/or number of stages. SideCar component size and configuration is limited for convenient shipping, so handling is practical without the need for mechanized lifting equipment.

Near each end of the AERATION HEADERS are ROLLER WEIGHTS (for concrete tanks) or weighted PLASTIC SHOES (for steel tanks) that support the assembly and prevent flotation during operation, permitting installation, positioning, and removal of each SideCar without draining the tank or removal of the RBC. The versatility of SideCar provides compensation to necessarily level the tops of diffusers when installed in installations with sloped floors. There are no submerged

brackets or anchors. If the manifold is installed inside the FRP cover of a multi-stage RBC, access ports, furnished with hinged covers, are located and cut into the lower cover wall to allow operation of the stage air-control valves.

The AERATION HEADERS are equipped with screw-in type coarse-bubble FlexCap DIFFUSERS to provide uniform air-flow rates (up to 10 SCFM per foot of RBC media length) with nominal head loss across the entire HEADER length. The ends of all headers are provided with removable DIFFUSERS hub assemblies.

Consistent with all quality materials and components of SideCar, Flexcaps are the preferred coarse bubble diffusers. This unique device is a product of exhaustive development, specifically for this RBC aeration application. In addition, FlexCap spacing on the SideCar Header is typically approx 6” O.C, creating the most versatile, reliable, maintenance-free combination of components. For more info click on Flexcap

Since peripheral velocity of motor-driven RBC media is typically about 1.0 FPS, the SideCar AERATION HEADER is necessarily offset from one to two feet to the descending side of the RBC center line, encouraging early entrance of air into the media. Accordingly, when locating and installing SideCars, attention to RBC rotation is important.

The typical Side Car aerator systems include an AIR SUPPLY MANIFOLD (for mounting along the RBC tank wall), with tees for each drop leg, a flexible connecter sleeve or elbow for air supply piping, and a removable cap on the dead end. The manifold is furnished with type 300 stainless steel or high-strength plastic SUPPORT BRACKETS and anchor bolts that mount conveniently on the RBC tank wall or support beams for fiberglass RBC enclosures.

For convenience in handling in cases where one or more RBC shafts comprise a treatment stage, multiple SideCar assemblies (depending on RBC length) are ganged on the AIR SUPPLY MANIFOLD with a single AIR CONTROL VALVE at the end.

SIDECAR AIR SUPPLY BLOWERS AND PIPING

For small to medium size plants, except in those rare cases when there are existing blowers that efficiently match SideCar air requirements blowers are often furnished as part of the SideCar aeration system. (see Basics of SideCar Systems Operation and Blower-to-SideCar Air Piping Design Practice.)

SideCar blowers are usually selected to simply provide process air flow with no standby capacity; RBCs can operate for days with reduced or intermittent aeration before problems gradually reappear. It is logical, however, except for the smallest plants, to employ two or three fractional capacity blowers providing operational flexibility, turndown capability, and partial or intermittent aeration for those rare cases when a blower must be taken out of service.

Regen blowers are delightfully quiet and reasonably efficient in the SideCar pressure range up to about 1000 CFM each. At higher air flows properly selected multi-stage centrifugal blowers become competitive and efficient.

Cost and performance of the SideCar aeration system is directly impacted by the design of the Blower-to-SideCar air supply piping (furnished by the system installer to meet plant specific conditions).

Except in the rarest cases, air flow to SideCars requires no metering and should not be throttled during normal service. SideCars are designed, when installed at like submergences with adequate size air-supply piping, to accurately distribute the air within ±10% over the entire system. No balancing or flow control is then required.

To summarize, blowers and air supply piping must be properly sized and selected to properly service the SideCars and minimize capital and operating costs. Simple, reliable systems best meet these needs.